将塑料箱清洗机运送到俄罗斯

2025年,一位俄罗斯客户购买了我们的塑料箱清洗机,用于频繁清洗装有碎肉的大量塑料箱。

俄罗斯客户经营一家专业的肉类加工厂,在肉类加工和包装过程中需要此类处理。传统的手工清洗效率低、耗时长,且无法满足严格的卫生标准。

在评估了多家供应商后,客户选择了我们的自动箱清洗机,并明确要求设备在尺寸、产能、清洗效果和结构设计方面必须完全符合其生产线标准。

设备配置与技术方案

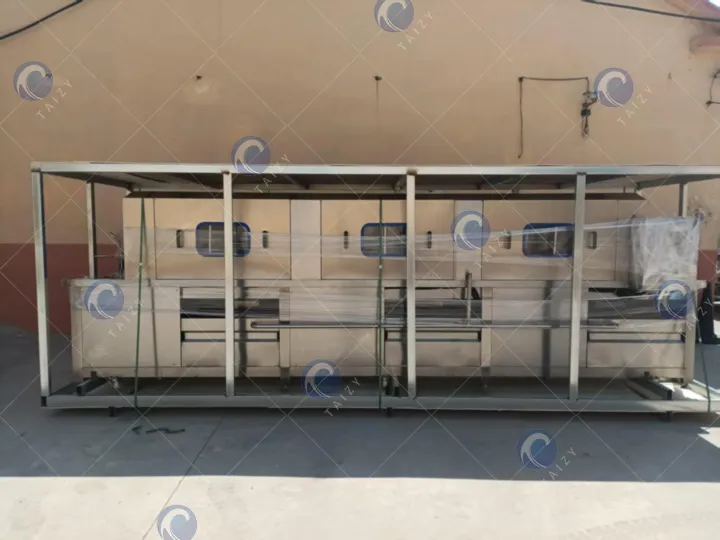

为了满足客户需求,我们定制的塑料箱清洗机尺寸为5000×1350×1600mm,可容纳600×400×300/200mm的塑料篮,清洗吞吐量达每小时100–150个篮子。

该机器设有三个清洗区:热水(含洗涤剂)→热水→冷水冲洗,彻底去除肉类残留。设备采用24kW电加热,工作电压为380V,50Hz,三相电源。

电源系统包括一台0.75kW的传送带,配有变频调速。每个区都安装了高效泵:预洗用3kW,冲洗用5.5kW,最终清洗用3kW。设备配备约70个球状喷嘴,另外还赠送10个喷嘴和2个加热管,供客户维护使用。

机器生产与交付

我们严格执行严格的生产标准。完成后,所有设备参数都经过细致验证,以确保完全符合合同要求。

根据客户规格,塑料箱清洗机采用带承重梁的木箱结构包装,便于堆叠运输,确保在国际运输过程中安全稳定。