Garlic Processing Plant | Garlic Splitting& Peeling Machine

| Machine Brand | Taizy Machinery |

| Main Equipment | Garlic splitting machine, peeling machine, sorting machine, washing machine |

| Warranty | 12 months |

| Capacity | 500-3000kg/h |

You can now ask our project managers for technical details

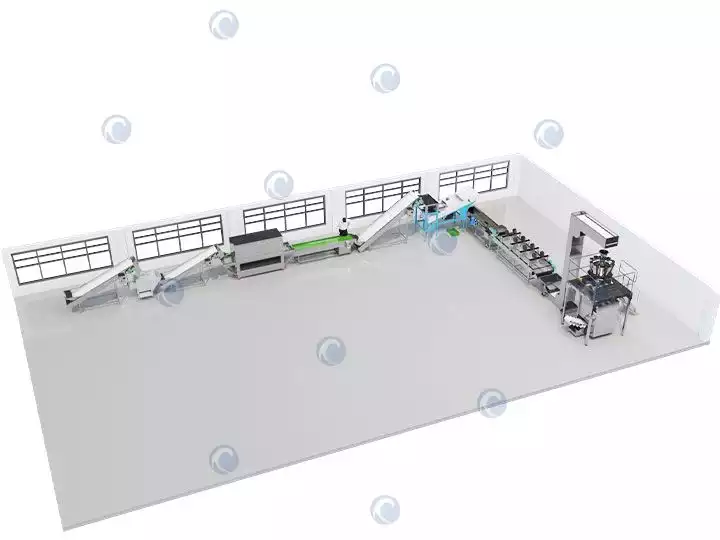

This commercial garlic processing plant is mainly used for processing raw garlic. The garlic processing machine of this line can quickly split, peel, clean, air dry, and pack garlic. The garlic processing equipment can enhance the economic added value for garlic, and the final product is widely used in food processing plants, restaurants, canteens and supermarkets. Therefore, this garlic splitting and peeling line is worthy to invest.

Introduction of Taizy garlic processing plant

The garlic processing line is the process of turning whole garlic into clean cloves, including splitting, peeling, picking, washing, drying, and packing garlic. This production line is perfect for garlic processing plants, seasoning production plants, and garlic retailers to invest. At present, our garlic processing equipment has been exported to the USA, Cambodia, Indonesia, Thailand, Colombia, Australia, Hungary, Mexico, and other countries.

Final products of the garlic processing plant

The clean garlic cloves are the final product of this garlic splitting and peeling line and we can provide packaging machines to package the garlic cloves. In addition, the clean garlic cloves can be reprocessed into high value-added products such as garlic flakes, garlic powder and garlic oil.

Main equipment of the garlic splitting and peeling line

The main equipment of this garlic processing plant includes an automatic conveyor, garlic splitting machine, garlic peeling machine, automatic color sorter, bubble washer machine, air dryer, garlic clove packing machine, etc. Taizy machinery can match different models for customers according to their output and demands. Each piece of equipment of this garlic processing line can also be purchased and used separately.

Garlic splitting machine

The garlic splitter machine quickly separates the garlic into individual cloves. The machine squeezes and separates the whole garlic into many small cloves by four wheels inside for the next peeling step. The machine does not damage the garlic cloves during the working process.

Garlic peeling machine

This garlic peeling machine is mainly applicable to the quick peeling of dry garlic. The garlic peeling machine is powered by compressed air and adopts bin type peeling structure. The rate of garlic peeling can reach 95%. And the machine will collect garlic peel automatically during peeling process by airflow.

Garlic sorting machine

The garlic color sorting process uses an automatic color sorter to pick garlic cloves. Garlic cloves with abnormal color such as spoiled or rotten and black are identified by the camera and then ejected by compressed air into the collection tank, while qualified cloves fall into the finished product tank.

Garlic washing machine

The garlic cloves are cleaned using a bubble fruit vegetable washer machine to remove dust from the surface of the cloves. Using the machine to clean garlic cloves saves time and effort and greatly improves work efficiency.

Garlic drying machine

We use continuous air dryers to air dry the cleaned garlic cloves in time. The cleaned garlic cloves need to be dried in time, otherwise, the moist cloves will easily deteriorate.

Garlic packing machine

Taizy Machinery offers a wide range of packaging machines to package garlic cloves. The patterns on the bags can be customized and the final product can be sold directly.

Benefits of garlic processing plant

All equipment of this industrial garlic processing line is made of high-quality food grade 304 stainless steel, which is very resistant to corrosion and abrasion.

This garlic processing plant uses automated machines instead of the traditional manual peeling and cleaning, which greatly improves efficiency and can process 500kg to 3000kg of garlic per hour.

This line is a small and medium-sized garlic processing line with a streamlined production process, very easy to install and easy to operate. The production is carried out in strict accordance with the national standard manufacturing process and the end product meets the requirements of food GMP sanitary conditions.