Vegetable Salad Production Line | Lettuce Processing Plant

The fully automatic vegetable salad production line is designed for the deep processing of vegetables. The whole lettuce processing plant includes automatic cutting, washing, air-drying and packaging. The final product will be ready for cooking or eating. The high economic added value of the processed vegetables and their popularity in the market make the vegetable salad production line a worthwhile investment.

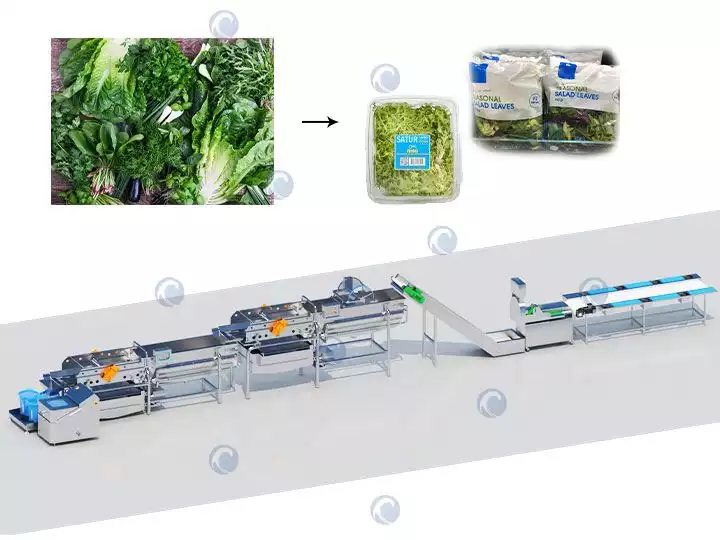

Final products of vegetable production line

The final products of the fully automatic vegetable salad production line are common in supermarkets. More and more people prefer to choose them instead of complete vegetables. The processed vegetables can be cooked or eaten directly without washing and cutting.

How to make clean vegetables by leafy vegetable processing line?

The main process of the vegetable salad production line includes sorting–cutting–washing–drying– packaging

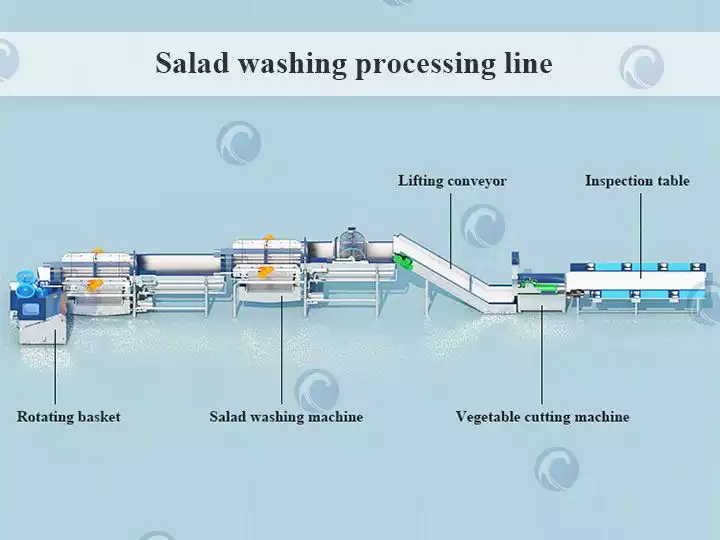

Main equipment of lettuce processing plant

The main equipment of this vortex vegetable salad production line mainly includes a picking table, automatic vegetable cutter, lifting conveyor, vortex washing machine, dehydrator and packaging machine. We can also provide different vegetable packing machines according to the specific needs of our customers. Below is the machine description.

Picking table

The picking table is set up to check the raw materials and to ensure that the quality of the vegetables is good. Before slicing, the fruits and vegetables need to be picked briefly to remove rotten and spoiled leaves or other impurities. In the fruit and vegetable vortex cleaning line, the picking table cannot be omitted.

Vegetable cutter

This automatic vegetable cutter is made of food-grade 304 stainless steel, equipped with safe switch at the door for safe operation. Changing different cutting knives can be used for slicing, shredding, and dicing of various vegetables.

Automatic lift

In order to increase the efficiency of the lettuce processing plant, we have set up an automatic lift specifically for lifting the cut vegetables into the vortex washer. The part that comes into direct contact with the vegetables uses a baffle plate on the lifting conveyor to pick food grade PE material that will not contaminate the vegetables.

Vortex cleaning machine

The vortex cleaning unit section mainly consists of vortex cleaners and vibrating screens. Unlike the bubble washer, the vortex washer has a powerful turbine that continuously drives the ingredients in the tank. The cut vegetables will be tumbled in the tank pool to achieve a thorough cleaning effect. In addition, there is no mesh belt in the vortex washer, which will not snag the leaves of vegetables. A vibrating screen is set at the outlet to shake off the water droplets on the surface of the fruits and vegetables.

Drying machine

The washed vegetables should be dehydrated in time. The drum built into this dehydrator is made of high quality food grade PE material, which lasts for a long time and does not contaminate the vegetables.

Vegetable packing machine

The washed vegetables can be packaged in various ways, the most common ones are mainly bagged, boxed, vacuum packed and heat shrink wrapped. Taizy Machinery can recommend the right packaging machine, packaging specifications and can also customize the appearance of the packaging for our customers according to their salad vegetable packaging needs.

Market expectation of clean vegetables

With increasing labor costs and standardized iterations of food and beverage products, the meal preparation process is using an increasing percentage of semi-finished products. Therefore, the prospect of the vegetable salad production line is great.

The process of purchasing vegetables and cleaning, cutting and matching, and making them is gradually replaced, and the procurement of clean vegetables, material packages, and semi-finished products and simple processing becomes a regular operation in the country. Especially in large chain restaurants, fast food and other markets, the popularity of clean vegetables is increasing.