Fruit and Vegetable Washing Line | Vegetable Washing Machine

The fruit and vegetable washing line is designed to process a wide range of materials through washing and drying equipment. Selling clean vegetables can increase the economic added value with a large profit margin. Using an automatic vegetable washing machine instead of traditional manual washing can greatly improve efficiency, which can also save labor costs and meet the needs of large production volumes.

Why do you need a fruit and vegetable washing line?

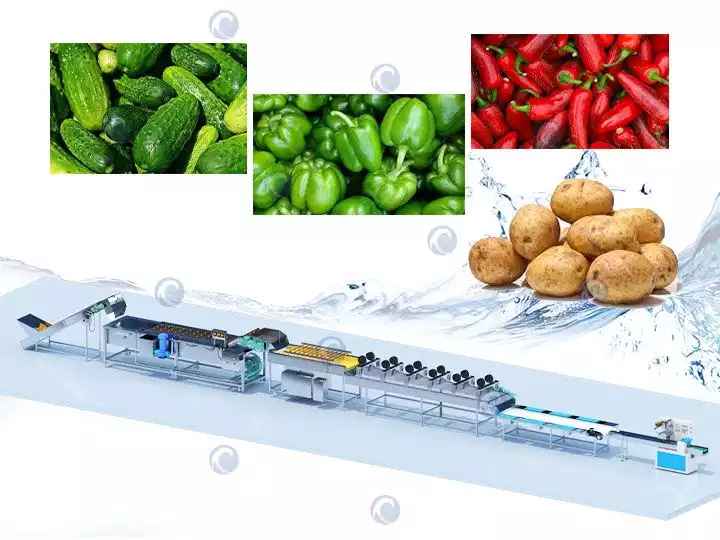

The complete fruit and vegetable washing plant have the main functions of continuous vegetable washing, drying, and packing. This automatic vegetable washing equipment can be used to process all kinds of fruits and vegetables, such as peppers, potatoes, radishes, tomatoes, cucumbers, etc. The capacity of this washing line is generally from 300 kg to 3 tons per hour, and customers can choose the right machine model according to their needs.

The machine is in great demand in the food industry and catering industries as it can ensure the quality of cleaning vegetables and fruits and help further the processing of vegetables and fruits. Besides, the advantage of saving labor as well as the amount of investment is also the main reason why they gain market pursuit.

3D video of fruit and vegetable washing line

Raw materials of fruit and vegetable washer plant

The vegetable washing line is suitable for use in farms, supermarkets, food processing plants, restaurants, etc. It can handle a wide range of materials, including lemons, tomatoes, potatoes, zucchini, eggplant, peppers, cucumbers, etc.

The following video shows the washing process of potatoes.

Main process of vegetable washing plant

The fruit and vegetable washing line use a more technological approach to stain and pesticide removal, first using the surfing method to get rid of dust and impurities on the surface of the fruit, and then rubbing the stubborn stains through the debridement process, thus thoroughly cleaning the fruits and vegetables. The clean fruits and vegetables are then quickly dried and packed. This vegetable cleaning and packaging line is currently selling very hot in the market.

Hoist conveyor

The conveyor is used to lift fruits and vegetables into the washing machine automatically, which can save manpower, and the speed of the conveyor can be adjusted. The height and width of the conveyor can be customized according to the customer’s raw materials and output.

Bubble washing machine

The new fruit and vegetable washing machine adopt bubble tumbling, brushing, and spraying technology, which can effectively clean the materials. The frame of the air bubble washing machine is made of high-quality SUS304 stainless steel, which meets the national food industry standard.

Hair roller remover machine

The hair roller de-mixer will clean the raw materials for the second time, which is an important step of fruit and vegetable washing line. The brushing of raw materials by the hair roller on the machine can thoroughly clean the stubborn dirt and other stains on the surface of fruits and vegetables, and at the same time, the cleaning will not cause damage to the surface of fruits and vegetables. In addition, the machine can be replaced with different hardness and length of rollers according to different raw materials.

Air dryer machine

Air dryers are mainly used for quick drying of clean fruits and vegetables for the subsequent stages of fruit and vegetable packaging. The conveyor belt of the new air dryer has been upgraded to a roller conveyor to improve drying efficiency.

Picking conveyor

After drying the raw materials, workers will select the defective or spoiled fruits and vegetables on the sorting table to ensure that the final product is of superior quality. Finally, these clean fruits and vegetables are ready for the packaging process.

Fruit and vegetable packing machine

Packaging is the last part of this fruit and vegetable washing line for the individual packaging of fresh vegetables. This packaging machine can realize different packaging forms such as bagged, boxed, etc. according to customer requirements.

Benefits of Taizy automatic vegetable washing line

- Taizy machinery provides a full range of services and can customize a suitable fruit and vegetable washing solution according to the customer’s raw materials, budget, and plant area.

- The whole line is highly automated, only two workers are needed for loading and picking. The machine has a large processing capacity and can handle 300kg to 3000kg of material. The common processing capacity of vegetable washing machine line is 500kg/h, 1000kg/h, 2000kg/h, 3000kg/h.

- Fruit and vegetable washing line uses a more advanced water treatment system to disinfect the water and decompose the residual pesticides. In addition, the machine can separate the raw materials from the washed sediment, which greatly improves the recycling rate of cleaning water and can save 85% of water, low energy consumption, saving energy costs for customers.

Necessary equipment for fruit and vegetable washing plant

For large vegetable washing plant, supermarkets, farms, restaurants, etc., often use a large number of plastic frames to store and transport fruits and vegetables. The automatic basket washing machine is our hot selling machine. The plastic baskets are sent to the high-pressure spray washing link through the conveyor belt for all-round reciprocating spray washing, which makes the plastic frames clean and makes them reusable. The washing machine is suitable for all kinds of food turnover baskets, crates, food boxes, plastic baskets, etc.

Jalapeno pepper washing machine sent to Mexico

Taizy Machinery exported a complete fruit and vegetable washing line to Mexico this year. The customer in Mexico has a food processing factory and looking for an ideal washing line for his jalapeno pepper. After finding us, he told our sales manager that he need a vegetable washing plant which can wash vegetables 1000kg each hour. Then our customer recommends this vegetable washing plant including a conveyor, a bubble washing machine, a dryer, and a picking conveyor. Now the jalapeno pepper washing plant has shipped to Mexico already.