Automatic Skinning: A Cost-Saving Solution for Onion Processing Businesses

Onion peeling is a key step in the onion food processing process, and peeling costs can account for a significant portion of the total cost of production. Traditional manual peeling methods are inefficient and require a lot of labor, which can lead to high peeling costs. Let’s explore how onion peeling machines can help onion food processing enterprises reduce costs and increase efficiency.

Onion Skinner Costs

Vegetable peeling is a key step in the onion food processing process, and peeling costs can account for a significant portion of the total cost of production. Traditional manual skinning methods are inefficient and require a lot of labor, which can lead to high peeling costs.

- Inefficiency. Manual skinning methods are time-consuming and labor-intensive. They can also be difficult to use, especially for large batches of onions.

- Contamination. Manual peeling methods can lead to contamination of the onion skin. The onion skin can contain bacteria and other contaminants, which can be transferred to the onion flesh during peeling.

- Additional disadvantages. In addition to inefficiency and contamination, traditional onion peeling methods can also lead to:

- Loss of product. Some of the onion flesh can be lost during manual peeling, which can lead to waste.

Benefits of machine for food processing

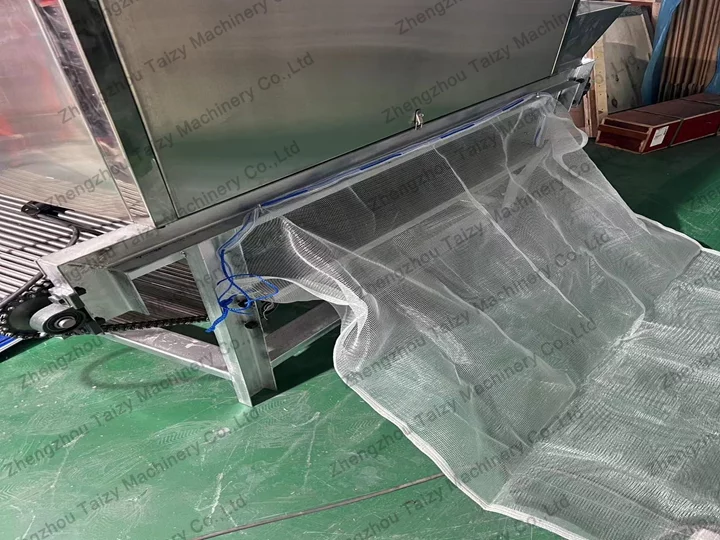

Taizy onion skinning machine has low energy consumption, easy cleaning, low failure rate, hygiene, and no pollution and other advantages. The machine is made of 304 stainless steel, which is in line with the hygienic standard of food processing machinery. It can be widely used in the catering industry, snack factories, vegetable processing factories, and so on.

Automatic onion peeler for consistency and standardization of production

Onion peeler machines offer a more efficient and consistent alternative to traditional methods. They can peel onions quickly and easily, and they can ensure that all of the onions are peeled to the same thickness. This can help to improve the quality and consistency of the final product, and it can also help to reduce waste.

In addition to consistency, onion peeler machines can also help to improve the standardization of production. They can ensure that all of the onions are peeled to the same size and shape. This can be important for businesses that need to meet specific product specifications.

Electric peeling machine to improve production efficiency

An electric peeling machine can peel onions at speeds of up to 1000kg/h. This can save businesses significant time and labor costs, especially for large-scale operations. Additionally, The onion peeler has come to facilitate factory production. Onions can be peeled quickly and easily without irritating the eyes. Workers can improve work efficiency and save time and energy. Such efficiencies can increase production and cost-effectiveness to meet the growing market demand for onions.

Taizy is a leading manufacturer of onion peeling machines. The company offers a wide range of machines to meet the needs of businesses of all sizes. Taizy’s high-capacity onion peeling machines are designed for businesses that process large volumes of onions. Welcome to learn more about our other food processing machines.