Automatic Vegetable Washing Line Can Achieve Good Cleaning Effect

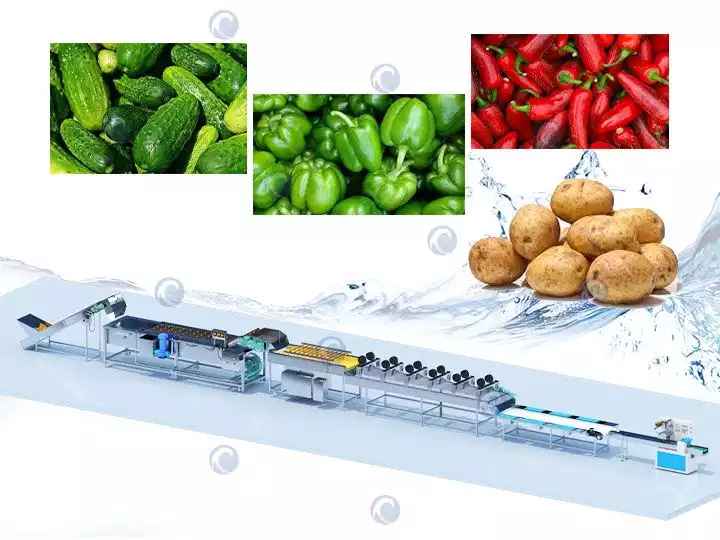

For pickle processing plants, food processing plants, washing a lot of vegetables is one of the daily tasks. So for the factory, how to clean vegetables to improve efficiency? We recommend the use of an automatic vegetable washing line.

Vegetable washing line adopts a bubble washing machine as the basis of cleaning, bubble washing is applicable to all types of vegetables, bubble generation device makes the material present tumbling state, more comprehensive vegetable cleaning. In most factories, vegetables must pass through multiple washing machines in a flowing operation to easily flush out the associated dirt. For the second cleaning, brush washers are generally used to make the vegetables even cleaner.

Vegetable washing line uses bubble vibration generated by high-pressure gas to clean fruits and vegetables. Effectively separating the sticky sediment on top of fruits and vegetables, and impurities, it achieves more effective cleaning of fruits and vegetables. Machine with ultrasonic cleaning function, more quickly remove the residues in the crevices of fruits and vegetables. The entire body of the structure is very solid, practical appearance, the machine with a battery valve switch, to achieve automatic water intake and automatic drainage function. The machine can be retrofitted with a water purification filter, which can purify the water, and has a filtering orifice plate at the bottom of the cleaning tank to isolate mud, sand and other debris.

For the sake of food health and safety, more and more businesses are choosing to use vegetable washing lines. In addition, we can customize the line to meet the customer’s needs, such as the de-mixer, manual picking table and packaging machine.

The automatic vegetable washing line improves the working efficiency and saves the labor cost for the food processing factory, and contributes to industrialization. Therefore, vegetable washing line is more and more popular.